The right wire stripper can make or break your electrical projects. Whether you’re a DIY enthusiast or professional electrician, selecting the appropriate tool is crucial.

Wire strippers come in three main varieties: gaged, self-adjusting, and adjustable. These essential tools serve specific needs and handle different wire gages. Picking the right wire stripper goes beyond knowing what’s available. You need to match the tool to your project’s requirements.

Let us walk you through the basics of wire strippers, especially if you’re new to electrical work. You’ll discover each type’s unique features. This information will help you select the perfect wire stripper that fits your needs.

Disclaimer

Hi, everyone; the details in this blog are meant purely for informational use only. Working with the electrical wiring involves inherent risks, including the potential for electric shock, fire hazards, and serious injury. Always prioritize safety: before starting any electrical tasks, make sure to switch off the power at the circuit breaker and confirm with a voltage tester. Use appropriate safety equipment.

This content does not constitute professional electrical advice. All electrical work should comply with applicable local codes and regulations. If you are uncertain about any procedure or your ability to perform it safely, please consult a qualified and licensed electrician. Using the information provided in this post means you acknowledge and take on all the risks related to the work you carry out.

What Are Wire Strippers and Why Do You Need Them?

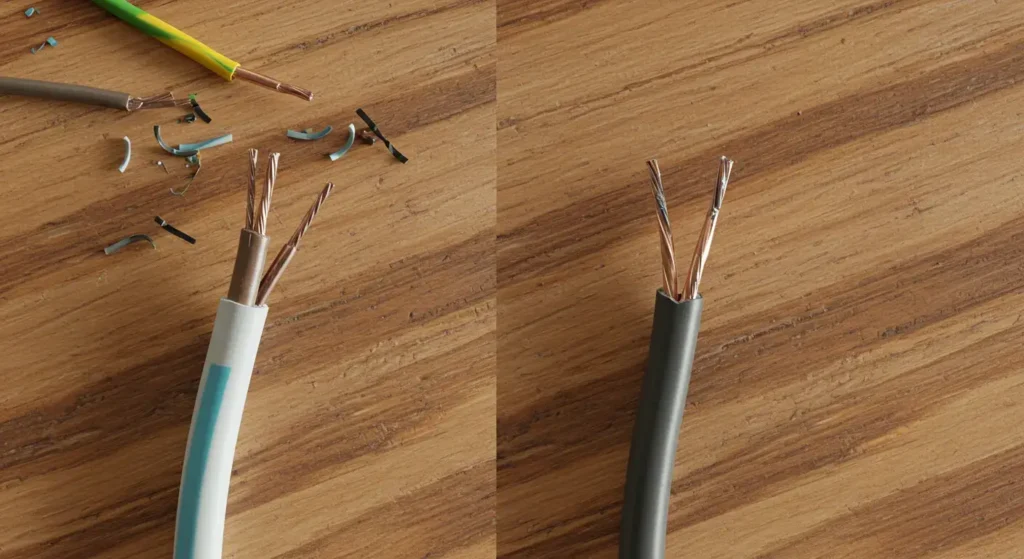

Wire strippers are specialized hand tools that remove insulation from electrical wires without damaging the metal conductor inside.

These tools look like pliers or scissors but serve a much more specific purpose in electrical work. The jaws contain slotted cutting blades sized to fit various gage wires while protecting the conductor from damage.

Simple functions of wire strippers

Wire strippers’ main goal is to safely and cleanly remove insulation from electrical wires. This vital task exposes the conductive material needed to make proper electrical connections. Quality wire strippers come with many more useful features:

- Tip/nose to hold and twist wires

- Various sized stripping blade slots for different gages

- Wire cutting capabilities

- Bolt shearing holes (typically for 6/32 and 8/32 sizes)

- Crimping areas for connectors

- Loop holes to create hooks in wires for screw terminals

You can use wire strippers by matching the wire to the right slot size, clamping down on the insulation, and pulling to remove it. The wire passes through the correctly sized slot, and the insulation comes off cleanly, leaving the conductor ready for connection.

Common projects requiring wire strippers

Professional electricians just need these tools to install, repair, or maintain electrical circuits in residential, commercial, and industrial settings.

The average DIY enthusiast will find wire strippers invaluable for home improvement projects like:

- Installing new light fixtures

- Wiring outlets and switches

- Setting up home automation systems

- Repairing appliances

- Automotive wiring repairs (lighting, sound systems)

- Electronics assembly and repair

Every project that involves connecting wires needs proper stripping first. You’ll also need specialized wire strippers designed specifically for coaxial, HDMI, or Ethernet cables.

Benefits of using the right tool for the job

The right wire stripper offers significant advantages over makeshift tools or methods. Properly stripped wires create good electrical contact and eliminate the risk of electrical failures, short circuits, and potential fire hazards.

Quality wire strippers give you precision—they remove exactly the right amount of insulation without damaging the conductor. This precision matters because damaged conductors create resistance, generate heat, and eventually fail.

Quality wire strippers come with many useful features that enhance their effectiveness. Here are some of the key functions:

These tools will save you time too. Quality wire strippers help you work quickly and consistently, especially during projects with multiple wire connections. Professional electricians and larger installations benefit even more from this time-saving aspect.

Safety comes first in electrical work. The right wire strippers reduce injury risk while working with wires. They provide controlled stripping that minimizes electrical hazards from exposed conductors.

Your electrical installations will last longer when you use the right tool. Clean connections resist corrosion and maintain conductivity over time.

Different Types of Wire Strippers for Beginners

Beginners need to know about different wire strippers before starting electrical work. Each type has its own benefits based on what you need to do.

Manual wire strippers

Gaged wire strippers are the most common manual tools you’ll find. They come with multiple notches corresponding to different wire gages. These tools have holes that match wires of different thicknesses. You can strip wires quickly without any adjustments. New users like these because they’re cheap and easy to use. You just need to match your wire to the right gage hole, clamp down, and pull.

Adjustable wire strippers give you another manual option. They have a single notch in each blade with a stop screw that lets you set the cut based on wire thickness. These tools take some practice but work great once you get used to them.

Automatic wire strippers

Self-adjusting (automatic) wire strippers make the job much easier for beginners. The spring-loaded teeth in the head sense the wire’s size when you squeeze the handles and cut into the jacket automatically. These tools cut and remove the insulation in one smooth motion. This saves you lots of time on big projects.

Some automatic strippers can handle several wires at once. This makes them perfect for commercial or industrial jobs. The biggest problem? They’re usually bigger and cost more than manual ones.

Combination wire stripper tools

Combination tools give beginners great value by putting multiple functions in one tool. These handy devices usually include:

- Wire stripping capabilities for various gages

- Built-in wire cutters

- Crimping functions for terminals

- Bolt-cutting capabilities

- Plier-style noses for gripping and bending

Many models have a pliers-style nose that’s perfect for pulling and looping wire. You’ll need fewer tools in your bag.

Specialty wire strippers

Specialty wire strippers handle specific jobs. Coaxial strippers take off both outer jackets and internal dielectric material from coaxial cables. Thermal wire strippers do a great job with insulation like P.T.F.E. and Teflon. Precision strippers help you work with tiny wires used in electronics repair.

Chemical wire strippers work best for magnet or enamel wires. They remove insulation without hurting delicate conductors. Your project’s success depends on picking the right stripper for the job.

Ultimately, the success of your electrical projects depends on using the right wire stripper for the job. Consider your specific needs and the types of wires you’ll be working with.

You just need to match the right wire stripper to your electrical tasks. The perfect tool choice depends on several key factors, not a one-size-fits-all solution.

Consider your wire types and sizes

Start by identifying the wire gages you work with most often. Your wire’s thickness (measured in AWG) determines which wire stripper will work for your projects. Most home electrical work uses wires from 10 to 18 gage, making this range perfect for general-purpose wire strippers. Electronics hobbyists and computer technicians work with thinner wires between 20 and 30 gage and need specialized strippers. On top of that, it matters what your wires are made of—copper, aluminum, and coated wiring each need specific tools because of their unique properties.

Evaluate handle comfort and grip

Basic handles might be enough for occasional wire stripping. In spite of that, comfortable handles become crucial if you spend full days on wiring projects. Quality rubber or silicone grips offer comfort and durability for long hours of use without hurting your hands. Professional-grade models come with ergonomically-shaped handles that reduce hand fatigue. Spring-loaded handles help a lot since you can operate them with one hand while holding the wire with the other.

Look for additional features

Today’s wire strippers pack plenty of useful functions:

- Crimping capabilities for cable ends

- Bolt cutters for trimming machine screws

- Needle-nose jaws for reaching into tight junction boxes

- Wire cutting functions

- Serrated gripping sections for holding wires steady

These extra features mean you’ll need fewer tools in your pouch.

Budget considerations

Wire strippers cost anywhere from under $5 to more than $35 for professional-grade tools. Price and quality don’t always associate directly, but investing in quality gives you longer tool life and more precise results. Mid-range options offer good value for occasional home projects. Professional users should think over high-end models with replaceable parts and precision engineering that can handle daily use. Note that self-adjusting models usually cost more than traditional gaged strippers.

Step-by-Step Guide: How to Use Wire Strippers Correctly

A good wire stripping technique helps you create safe and reliable electrical connections. Let me show you how to get perfect results every time.

Preparing your workspace

Safety should be your top priority when you work with electrical wires. Here’s what you need to do before you start:

- Turn off power to the circuit at the breaker box

- Use a voltage tester to check if the wire is live – power is still present if the tester lights up or beeps

- Pick a well-lit area so you can see everything clearly

- Put on insulated gloves to protect yourself

- Keep your tools close by to optimize your work

You’ll find precise work much easier with a clean, flat surface that reduces distractions and hazards.

Identifying wire gage

The right gage identification helps prevent wire damage. Standard nonmetallic (NM) cable’s insulation color makes it easy to identify:

- White sheathing: 14-gage wire

- Yellow sheathing: 12-gage wire

- Orange sheathing: 10-gage wire

If you’re not sure, try a wire gage tool or test the wire in different stripper notches until you find one where it fits snugly without too much compression.

Positioning the wire correctly

Put the wire in the right notch that matches its gage. The stripper should be about ½ inch from the end for a standard strip job. The wire needs to sit straight and line up properly in the groove to get even results.

Some electrical devices need specific strip lengths, so check your device’s specs first.

Stripping technique for clean results

After you position the wire:

- Close the handles firmly until they grab the insulation—not the conductor

- Give the stripper a twist to cut all the way around

- Pull the stripper smoothly toward the wire’s end

- Look for any nicks or cuts in the exposed wire—if you find damage, cut that part off and start over

Take a look at stranded wire to make sure no strands are cut. You might need a different sized notch or to cut around more if the insulation resists coming off.

Conclusion

Wire strippers are vital tools for anyone who works with electrical projects. You need to understand their types and select the right one. Becoming skilled at proper techniques will give a safe and effective wire connection every time.

Safety is crucial in electrical wire work. Your wire stripper must match specific project requirements. Using correct stripping procedures protects you and your electrical installations.

Quality wire strippers offer longer life and consistent results. Start with simple manual strippers to handle basic projects. You can upgrade your tools as your skills improve and projects become more complex. With proper techniques and awareness of wire gages, your electrical work will meet professional standards consistently.