Quick Summary: Wedge Anchors vs Sleeve Anchors: Which is Best for Concrete?

- Content Type: Hand Tested Review

- Affiliate Link Present: No

When deciding between wedge anchors and sleeve anchors, picking the correct fastener is crucial for your concrete project’s success. Both are common choices to secure items to concrete, but their strength and uses differ a lot. Wedge anchors can handle loads as heavy as 6000 pounds or even more, which makes them perfect for heavy-duty tasks. On the other hand, sleeve anchors hold weights ranging from 200 to 1000 pounds making them better for medium-duty work.

What is a wedge anchor? This is a tough fastener made to deliver the strongest grip out of all mechanical anchors. It works best when attaching heavy items like structural steel or machinery to solid concrete. What about a sleeve anchor? This type offers more flexibility and can be used not just with concrete but also with materials like brick and block. Concrete wedge anchors are built for solid concrete and focus on strength, while sleeve anchors handle lighter loads and work well with softer surfaces.

If you work as a professional contractor or enjoy DIY projects knowing what sets different anchors apart is key to completing your project . This guide breaks down how these anchors function, the steps to install them, their strength limits, and when each type is most useful. By the time you finish reading, you’ll have a clear idea of which anchor fits your concrete project best.

Disclaimer

Affiliate Disclaimer

I want to be 100% honest with you. Some links you see in my post are ‘affiliate links’. This just means if you click one of my links and then buy a tool, I get a very small money from the shop.

This does not cost you any extra money at all. The price is the same for you.

This small help lets me keep this blog alive and test more tools for you. Please know, I only link to tools I have used myself or received a verified review of the tool and believe are good. My words and my review are my own, nobody pays me to say nice things. Thank you for your support!

Image Information

All product images used in this post are provided by the author and claimed to be their own usage. According to the author, these images are either self-clicked, taken during hands-on testing, or screenshots captured for review purposes. If you believe any image violates your rights, please contact us for proper credit or removal.

Price & Stock Information

The product prices and availability mentioned in this post are accurate as of the time of publishing. However, prices may change on the seller’s website without notice. Please always check the latest price and stock status on the official product page before making a purchase decision.

How Sleeve and Wedge Anchors Function

Learning how sleeve anchors and wedge anchors operate helps you choose for concrete work.

What a sleeve anchor is and how it works

A sleeve anchor comes with a bolt, nut, washer, and an expanding sleeve around the bolt. The sleeve part is what gives this fastener its name and its holding power. When you tighten the nut, the sleeve spreads out and pushes against the sides of a pre-drilled hole. This creates a strong hold. People can use sleeve anchors in materials like concrete, brick, or blocks, so they work well for both light and heavy fastening jobs.

- Expansion type anchors used to fasten fixtures into a variety of base materials

- Versatile and ideal for concrete, or masonry

- Common applications include door and window frame installations, mounting fixtures on walls, shelving and storage

What is a wedge anchor and how does it work?

Wedge anchors include a threaded stud, a strong stainless steel expansion clip, a nut, and a washer. These anchors use a straightforward method to achieve strong holding power in concrete. Tightening the nut pulls the anchor body upwards. This movement forces the expansion clip down the cone-shaped end of the anchor. As a result, the clip spreads out and wedges itself between the anchor and the concrete surface, locking it in place. Wedge anchors work with solid concrete and should not be installed in other types of base materials.

- Material: Our Wedge Anchors Are Made Of High Quality Carbon Steel And Are Galvanized To Make The Wedge Anchors Much More…

- Use: Wedge Anchors Are Ideal For Attaching Items To Concrete, Sloped Buildings Or Metal Plates, Steel And Wood.

- Product: Each Wedge Anchor Has A Nut And Washer Already Placed On It For Your Convenience And Ease Of Use.

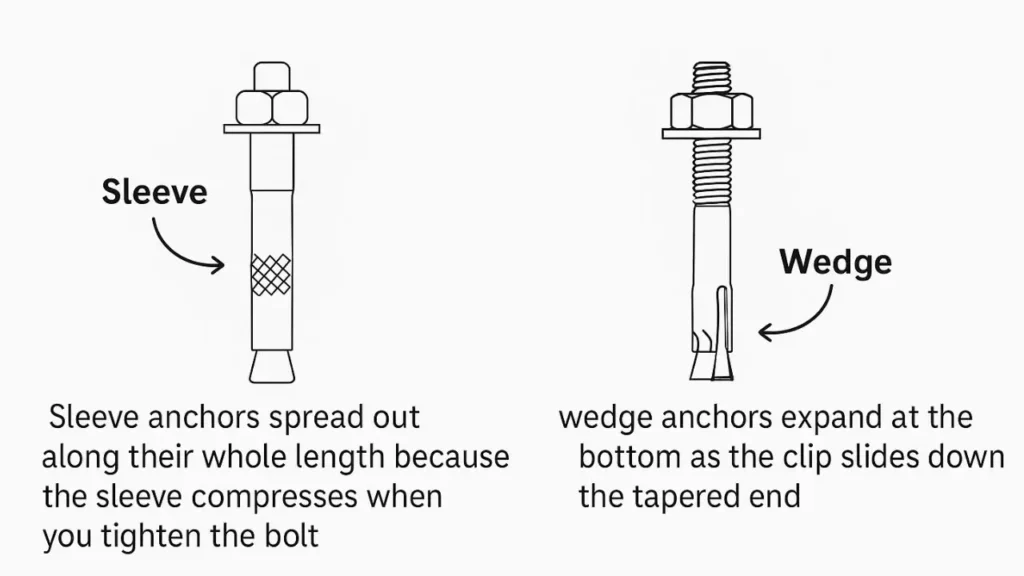

Expansion mechanism: sleeve versus wedge

The main difference comes from how they expand. Sleeve anchors spread out along their whole length because the sleeve compresses when you tighten the bolt. On the other hand, wedge anchors expand at the bottom as the clip slides down the tapered end. This difference gives wedge anchors better holding power. They can handle very heavy loads over 6000 lbs, while sleeve anchors work for lighter loads between 200 and 1000 lbs.

Types of threading and nuts used

Both anchor types include threaded parts but differ in key ways. Wedge anchors have a fully threaded design that works with materials of different thicknesses while keeping the same embedment depth. During installation, you secure a nut on the exposed threads to shield them when hitting the anchor with a hammer. Sleeve anchors, on the other hand, offer four head styles: hex flat, acorn, and round. Both types are available in stainless steel or zinc-plated carbon steel making them suitable for a range of environmental conditions.

Choosing the Right Anchor Based on Materials and Environment

To pick the right anchor, you need to consider material compatibility and assess the environmental conditions of your job.

Concrete wedge anchors: Ideal to use on solid concrete

Wedge anchors work only in solid concrete. You should never use them in brick, block, or mortar joints. Concrete must be cured before installation and should be at least 28 days old. Installing them sooner can weaken holding strength over time.

Concrete sleeve anchors: flexible choice for various materials

Sleeve anchors are much more versatile compared to wedge anchors. They perform well in concrete, bricks, blocks, and even mortar, which makes them a great option for jobs using mixed materials or where the material quality isn’t consistent.

Corrosion resistance: comparing zinc-plated and stainless steel anchors

The ranking of corrosion resistance goes from zinc-plated at the bottom to hot-dipped galvanized in the middle, and stainless steel at the top:

- Zinc-plated anchors: These give basic rust protection and work well in dry indoor spaces .

- Hot-dipped galvanized: These offer better rust resistance making them good for wetter or outdoor conditions.

- 303/304 stainless steel: These perform well against rust in most places.

- 316 stainless steel: These provide the best protection even holding up in saltwater areas.

Choosing between indoor and outdoor environments

To save money for indoor use without moisture, zinc-plated anchors work well. For outdoor setups at least hot-dipped galvanized anchors are a must. In rough conditions like chemical plants, near pools, or by the ocean, 316 stainless steel anchors are necessary. These anchors cost about double the price of 303 or 304 stainless steel options.

Steps To Install and Tools You’ll Need

Installing anchors decides if they stay secure or risk failing. Let’s break down key differences in the installation process for sleeve anchors and wedge anchors.

Comparing hole size and depth: sleeve vs wedge anchors

Drilling needs differ based on the type of anchor. Wedge anchors demand holes that match their diameter . On the other hand, sleeve anchors need holes that are a bit bigger than their diameter. For example, a 5/16-inch wedge anchor fits into a 5/16-inch hole, but a 5/16-inch sleeve anchor goes into a 3/8-inch hole. The minimum embedment depth also changes depending on the anchor’s diameter. Wedge anchors need greater depth to provide stronger holding strength.

Drilling tips and hole cleaning

You need a hammer drill with a carbide-tipped bit that meets ANSI standards to install both types of anchors. Cleaning the holes is crucial since not doing it can cut the load capacity by half or even more. Use a blow-out pump or compressed air to clear out drilling dust when working with mechanical anchors such as wedge or sleeve anchors.

How to install sleeve anchors step by step

- Make a hole the same size as the sleeve anchor’s diameter. Drill it about 1/2″ deeper than the length it needs to hold.

- Clear out all dust and bits from the hole .

- Keep the nut level with the anchor’s top to keep the threads safe.

- Push the anchor through the object you’re securing into the base material below.

- Tighten the nut using your fingers until it’s snug.

- Take a wrench and turn the nut 3-4 full turns to secure it .

Instructions to install wedge anchors step by step

- Make a hole that matches the size of the wedge anchor.

- Remove all dust and debris .

- Put the nut on the end of the anchor to protect the threads.

- Use a hammer to drive the anchor into the hole until the threads sit below the surface.

- Turn the nut about 3 to 4 full times to tighten it.

Mistakes people tend to make

The most common issues include using the wrong hole size, not cleaning the hole , setting the anchor at an improper depth, or tightening it too much. Turning the nut too hard risks damaging the anchor or concrete, which makes it less secure. If you sink a concrete screw anchor too far, you might strip the concrete around it and weaken its ability to hold.

Strength Limits, Applications, and Pricing

Load capacity plays a key role in deciding which anchor to use for concrete tasks. The strength difference between sleeve anchors and wedge anchors becomes clear when looking at how much weight each can handle.

Weight support: 200–1000 lbs compared to 6000+ lbs

Sleeve anchors can handle weights between 200 and 1000 lbs making them a good option for lighter to medium-duty jobs. In contrast, wedge anchors provide far greater strength managing loads of 6000 lbs or more. This big gap in load limits makes wedge anchors the strongest choice among mechanical anchors available today.

Recommended uses: shelves light fixtures vs heavy machinery, steel frameworks

Sleeve anchors work great when attaching items like electrical boxes flat-screen TVs, shelving, or handrails. Many people use them to remodel homes to install signs or mount medium-duty equipment.

Wedge anchors though, are better suited to tasks that involve structural elements heavy equipment large antennas, fire sprinklers, or even elevators. They play a key role in keeping heavy machinery attached to concrete floors in factories or holding steel columns and beams to concrete bases. Experts agree wedge anchors can handle vibrations well, which keeps machinery steady even under intense use.

Comparing installation times

When it comes to how you can install them, sleeve anchors take about 2 to 3 minutes to set up each one. On the other hand, wedge anchors need more precise drilling and fastening work taking closer to 5 to 10 minutes per anchor.

Choosing between cost and strength

Sleeve anchors cost less, which makes them a good choice to handle medium-duty tasks. Wedge anchors, while more expensive, offer better load support and toughness. Spending more on wedge anchors is often worth it when used in structural setups or situations where anchoring failure would be unacceptable, like securing high-value equipment.

Comparison Table

| Feature | Wedge Anchors | Sleeve Anchors |

|---|---|---|

| Load Capacity | Up to 6000+ lbs | 200–1000 lbs |

| Base Material Compatibility | Solid concrete only | Concrete, brick, block, and mortar |

| Hole Size Requirement | Exact match to anchor diameter | Slightly larger than anchor diameter |

| Components | Threaded stud body, stainless steel expansion clip, nut, washer | Threaded bolt, nut, washer, expanding sleeve |

| Expansion Mechanism | Expands primarily at the bottom | Expands along entire length |

| Best Applications | Structural steel, heavy machinery, elevators, fire sprinklers | Shelving, electrical boxes, TVs, handrails |

| Installation Time | 5–10 minutes per anchor | 2–3 minutes per anchor |

| Available Finishes |

– Zinc-plated – Hot-dipped galvanized – 303/304 stainless steel – 316 stainless steel |

– Zinc-plated – Hot-dipped galvanized – 303/304 stainless steel – 316 stainless steel |

| Head Style Options | Not mentioned | Hex, flat, acorn, and round |

| Vibration Resistance | Exceptional | Not mentioned |

Conclusion

The choice between wedge anchors and sleeve anchors depends on what your project needs and the type of base material involved. Wedge anchors work best when you need heavy-duty support with strong holding power. They are the go-to solution to secure heavy machinery structural steel, or critical parts to solid concrete due to their impressive strength of over 6000 pounds.

Sleeve anchors, on the flip side, bring great versatility that wedge anchors just cannot offer. They function well in different base materials like brick concrete block, or mortar making them a smart pick for medium-duty tasks. Plus, their simpler and quicker installation can save time on projects where many anchors are required.

Installing both types of anchors requires using the proper method to get the best results. No matter what kind you choose, you have to drill , clean the holes , and tighten them right. Using the wrong method can lower the holding strength even with a top-quality anchor.

Costs matter when deciding too. Sleeve anchors come at a lower price than wedge anchors, which works well for projects needing medium-strength loads. But paying more for wedge anchors makes sense when avoiding failure is critical or when protecting expensive equipment.

Before you dive into your next concrete anchoring task, take time to figure out what you need. Think about the base material how much weight it needs to hold, what kind of environment it will be in, and how much money you can spend. Picking the right anchor often makes the difference between a project that works and one that ends in frustration.

Key Points

Knowing the key differences between wedge anchors and sleeve anchors matters a lot when choosing the right fastener to use in your concrete project.

• Load capacity varies a lot: Wedge anchors can hold over 6000 pounds and work well in heavy-duty jobs, but sleeve anchors are meant to hold between 200 and 1000 pounds and are better for medium-duty needs.

- Material compatibility differs a lot: Wedge anchors work in solid concrete, but sleeve anchors can be used in concrete, brick, block, and mortar.

- Installation needs are not the same: Wedge anchors need exact holes and must go deeper, but sleeve anchors need bigger holes and are easier to install.

- Picking the right anchor for the job matters: Use wedge anchors with heavy machinery or structural steel. Sleeve anchors work better for shelves, fixtures, or electrical boxes.

- Environment affects finish selection: Pick zinc-plated for dry indoor areas hot-dipped galvanized for outdoor spaces, and stainless steel for tough conditions.

Choosing the right anchor depends on weighing load demands, compatibility with the base material how hard it is to install, and the costs involved. Installing it is essential regardless of the anchor type. Even skipping proper hole cleaning can cut its load capacity by half or more.

FAQs

Q1. What sets wedge anchors apart from sleeve anchors? Wedge anchors can handle heavier loads (6000+ lbs) and work best with solid concrete. Sleeve anchors, on the other hand, handle lighter loads (200 to 1000 lbs) but work for concrete, brick, and block. Wedge anchors expand at the base, while sleeve anchors spread out along their whole length.

Q2. Which anchor type works best for heavy-duty tasks? Wedge anchors work well for heavy-duty tasks. They handle loads over 6000 lbs making them a solid option to secure heavy machinery structural steel, and key components to concrete.

Q3. Can sleeve anchors work in materials besides concrete? Sleeve anchors can work in more than just concrete. They also hold up in brick, block, and mortar. Their adaptability makes them a good choice when dealing with mixed materials or uneven base quality.

Q4. How are wedge and sleeve anchor installation steps different? Wedge anchors need holes that are the same size as the anchor itself. Sleeve anchors, on the other hand, require larger holes to fit. Installing wedge anchors often takes more time, around 5 to 10 minutes per anchor, since they need to be embedded deeper. Sleeve anchors are quicker to put in about 2 to 3 minutes for each one.

Q5. What should you think about when deciding between wedge and sleeve anchors? You should look at the type of base material, the load capacity you need, the conditions where the anchors will be used, and how much you’re willing to spend. If your project is heavy-duty, wedge anchors might work better because of their higher strength. Sleeve anchors are a flexible option for medium-duty jobs. You should also think about how hard they are to install and how much time the process will take.