Quick Summary: How to Choose Expanding Screws for Heavy-Duty Metal

- Content Type: Guide

- Last Updated: July 29, 2025

- Fact-Checked By: Author Himself

- Best For: Ideal for those seeking durable and corrosion-resistant anchor bolts for outdoor applications.

- What’s Great: The stainless steel bolt offers superior strength, longevity, and resistance to rust and weathering.

- What’s Not: The rusted anchor bolt may fail over time, compromising structural integrity due to corrosion.

- Affiliate Link Present: Yes

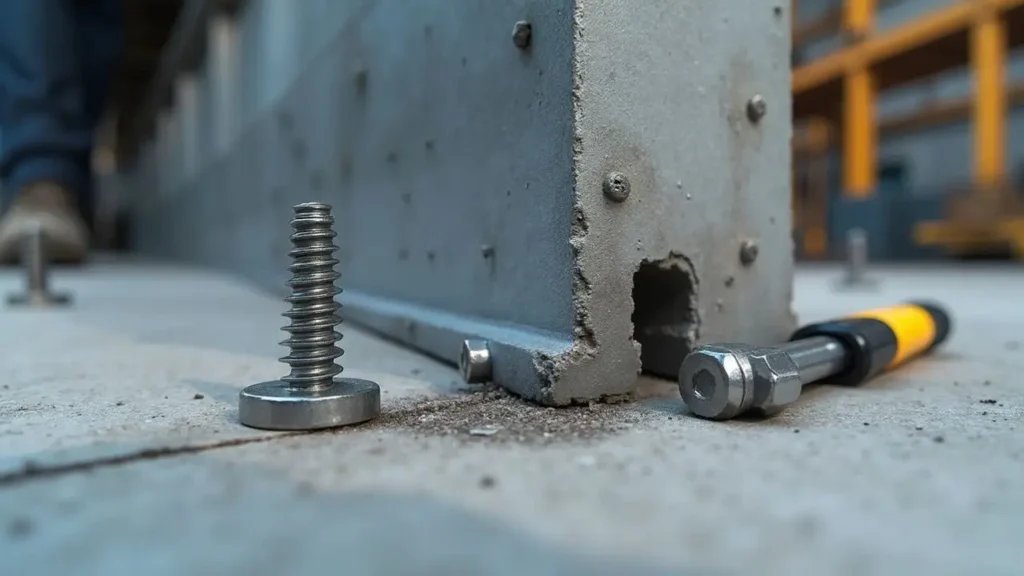

Expanding screws are vital in building and engineering to hold heavy things to strong surfaces. Choosing the right fastener for metal projects is important as it can control failures and keep things in place. Also known as wall anchors or expansion anchors, these fasteners provide strong grip where regular screws can’t.

Choosing the right anchor screws for metal means considering a few things. Expansion fasteners come in different types, each for specific uses and weight loads. Wedge anchors which are known for their strong grip and can handle pull-out force work well in most cases. Stainless steel expanding bolts for metal stands out because they resist rust better. It’s a lot to sort through. Also learning how to install expansion screws is important as overloading them beyond what the manufacturer recommends can cause them to fail or damage.

This guide covers everything you need to know to choose expanding screws when working with metal. It looks at load demands, compares the top heavy duty options, gives you tips to install them and helps you decide the best anchor based on environmental conditions. Whether you’re attaching machinery to steel frames or hanging overhead fixtures, this guide has got you covered to keep your metal projects solid for life.

Disclaimer

Affiliate Disclaimer

I want to be 100% honest with you. Some links you see in my post are ‘affiliate links’. This just means if you click one of my links and then buy a tool, I get a very small money from the shop.

This does not cost you any extra money at all. The price is the same for you.

This small help lets me keep this blog alive and test more tools for you. Please know, I only link to tools I have used myself or received a verified review of the tool and believe are good. My words and my review are my own, nobody pays me to say nice things. Thank you for your support!

Image Information

The images used in this guide are AI generated, we use these images because we thought these can explain everything in a easy way. Hope you will like it.

Price & Stock Information

The product prices and availability mentioned in this post are accurate as of the time of publishing. However, prices may change on the seller’s website without notice. Please always check the latest price and stock status on the official product page before making a purchase decision.

Load Demands to Consider in Metal Projects

Choosing the right expanding screws to use with metal structures starts with knowing the loads they will be under. Every installation has its own challenges so you need specific types of fasteners to be safe and to last.

Thinking About Tensile and Shear Loads on Steel

Building steel structures needs thought around how both tensile and shear forces act. Tensile forces pull parts apart stretching bolts along their length. In contrast shear forces push in a way that tries to slice across a bolt. The link between these forces matters. Shear strength in steel tends to be about 0.6 of its tensile strength. Compression yield strength is 1.2 times tensile yield strength. The ultimate strength during bending can go up to 2.2 times the ultimate tensile strength.

To use expanding bolts in steel, you need to choose fasteners rated for the load they will handle. Fasteners made for straight pulling can break if pushed from the side. For this reason, projects like railings often need fasteners with strong shear resistance. On the other hand overhead fixtures require fasteners that can handle high tensile strength.

Loads in Machinery Mounting

Machinery mounting gets tricky because of dynamic loads. These loads change in strength or direction over time. They are:

- Vibratory loads from moving parts

- Impact loads from sudden bumps or hits

- Cyclic loads that repeat over time

- Shock loads from quick movements

Vibration at 16Hz causes trouble to floors and mountings. Machines running at these vibrations put constant stress on fasteners which have to resist loosening and wearing out. Choosing the right anchor screws for metal under high vibration involves considering both the vibration strength and its frequency.

Required Embedment Depth to Anchor Heavy Loads

How deep you embed an expanding screw decides its holding strength. To secure anchor bolts in light to medium-duty tasks, you need to embed them at least 7 or 8 inches into the concrete. Heavy-duty situations demand a depth that equals 10 times the bolt’s diameter. Post-installed adhesive anchors however, work within a range of 4 times the anchor’s diameter at minimum and 20 times at most.

Going deeper with embedment boosts pullout resistance when handling heavier loads. If the embedment isn’t deep enough, expanding screws might fail earlier even if their diameter is right. Concrete’s compressive strength also plays a major role in determining the load capacity of expanding screws, so you must consider that while anchoring.

Top 4 Expanding Screws to Handle Heavy-Duty Metal Work

Choosing the proper expansion anchor can have a big impact on how well a project with metal structures turns out. Different types work better with certain metal tasks.

- UNIVERSAL FIT KIT – Great Assortment Push Retainer Kit with 12 popular size, fitting for door trim, radiator shield yoke…

- SAVE TIME AND MONEY – You can find 240PCS automotive push type retainer kit in the box and no need to go to a auto parts…

- HIGH QUALITY – High quality material with heavy-duty construction for durability, this push type retainers set would not…

Wedge Anchors to Connect Structural Steel

Wedge anchors work great in connecting structural steel because they have solid holding strength and handle vibrations well. Made using sturdy carbon or stainless steel, these anchors lock in place by wedging forces over a broader area. The expansion clip has grooves that dig into the base material when the anchor expands locking it in place . To secure structural steel, wedge anchors perform with strong pull-out strength and meet ICC approvals when needed. The sleeve fits the shank so you do not need to change the hole. These anchors can be removed and reused making them handy for construction projects.

- Material: Our Wedge Anchors Are Made Of High Quality Carbon Steel And Are Galvanized To Make The Wedge Anchors Mu…

- Use: Wedge Anchors Are Ideal For Attaching Items To Concrete, Sloped Buildings Or Metal Plates, Steel And Wood.

- Product: Each Wedge Anchor Has A Nut And Washer Already Placed On It For Your Convenience And Ease Of Use.

Sleeve Anchors to Fasten Metal in Flexible Ways

Sleeve anchors work well with many types of building materials because they offer flexibility. They expand all the way around, which gives steady holding power in materials like brick, cement, concrete, and blocks. Manufacturers make these anchors in multiple head styles, including hex, acorn, flat, and round so you can use them for many jobs with just one type of anchor. Their wide bearing surface helps in softer concrete by lowering the pressure on the concrete surface. People often use them for things like attaching decking, door frames, or light fixtures. The expansion principle behind sleeve anchors lets them fasten materials , with the stud pulling through the sleeve to lock it in place.

- Expansion type anchors used to fasten fixtures into a variety of base materials

- Versatile and ideal for concrete, or masonry

- Common applications include door and window frame installations, mounting fixtures on walls, shelving and storage

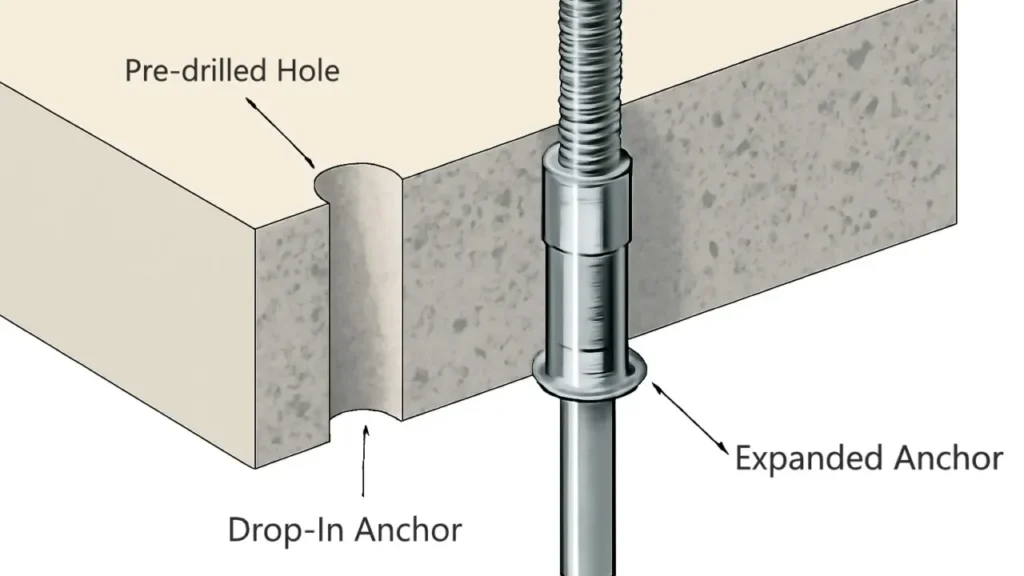

Drop-In Anchors to Hold Metal Fixtures Overhead

Drop-in anchors come with a steel outer shell that has internal threads and a special expansion cone. These are made to work with concrete surfaces. They work well in overhead setups such as hanging pipes, sprinkler systems, and anchor points that can be removed later. A big plus is their ability to sit flush with the surface, which is great when a smooth finish matters. To install them, you drop the anchor into a hole that’s been drilled beforehand and use a setting tool to push the body over its cone. Hilti’s HDI drop-in anchors save effort during overhead work in post-tension slabs or precast panels by skipping the need for hammering. This improvement helps make the job faster and easier.

- [Package Include]: In this package, you can get 20pcs 3/8″-16 premium zinc plated concrete knurled drop in anchors, suff…

- [RELIABLE AND DURABLE]:Our knurled drop-in-anchor are made of high quality iron and zinc surface, corrosion and rust res…

- [Function] 3/8″ Inch premium iron material knurled drop in anchors: 1-9/16″ hole depth and 1/2″ hole diameter, use with …

Concrete Screws (Tapcon®) to Mount Directly Onto Metal

Tapcon® concrete screws help attach metal to concrete and . Their sharp threads cut the surface as you install them forming a tight hold. These screws pass strict tests for fire resistance and seismic conditions working well in cracked or solid concrete. To install them, you need to drill a hole, clean it, and drive the screw in—no hammer needed. People use them in many areas like ventilation electrical work, and setting up steel frames or rails. For metal roofing on concrete, ZAC Anchors and Scots SSC anchors give a durable and cost-effective solution with strong long-term performance.

- Eliminates bit slip with star recess

- Works in all masonry-based material including concrete, block or brick

- Use these screws for a variety of projects including fixing sill plates, electrical equipment, 2 ft. x 4 ft. and many ot…

How to Install Expanding Screws in Metal

Expanding screws hold better and stay safer when used on metal, but you must follow all the steps to make them work well.

Making Pilot Holes in Steel or Concrete

To install expanding screws , match your drill bit to the screw’s outer diameter. This is about 2mm larger than the screw itself. If you’re drilling into steel plates first, go with cobalt or carbide-tipped bits. Use a variable speed drill with enough power and keep your pressure steady while holding the drill straight. If you’re working on concrete after metal, switch to a hammer drill. Make sure you’re using an ANSI-tolerance carbide-tipped bit for the job.

Expanding Screws with a Torque Wrench

Start by tightening the nut on the expansion bolt using a torque wrench. While doing this, pay attention to the resistance it creates. The nut’s tightening expands the bolt head, which presses the metal sleeve into the hole to secure it. A torque wrench when set up, avoids applying too much force and ensures that the bolt’s expansion is enough. The bolt’s slanted design helps it grip because it increases friction when expanded.

Steps to Prevent Damage in Thin Metal Plates

Thin metal plates ones under 2mm, can become damaged if you apply too much torque. To avoid this problem, tighten the nut at first. Then remove it, position the fixing piece so it fits the hole , and reattach the bolt using a washer. Spring washers are ideal since they help keep the bolt from coming loose over time.

Tips To Use Expansion Screws for Hollow Metal Walls

Typical expansion screws do not work well in hollow metal walls. You can try other options like toggle bolts, which fit into 1/2″ holes, or rivnuts. Rivnuts act as rivets that come with built-in threads for regular screws. In cases involving hollow aluminum, sheet metal screws can be helpful, or you might use through-bolts with washers. This spreads the force across the thin aluminum.

Choosing the Best Anchor for the Environment

The performance and life of expanding screws depends on the environment. Choosing anchors for the specific conditions will keep both strength and durability over time.

Corrosion Resistance in Outdoor Installations

Outdoor projects need materials that can resist corrosion so moisture and weather don’t damage. Stainless steel expanding bolts are good in coastal areas and chemical plants. They offer great protection against saltwater and harsh chemicals. Industry studies show that using materials like stainless steel will improve durability by 40% in tough conditions. In milder conditions, zinc plated or galvanized screws will give decent protection at a lower cost. Aluminum fasteners are another option. They won’t rust but will develop an oxide layer over time which will protect them from further damage.

Fire-Rated Anchors for Industrial Facilities

In industrial environments, safety rules often require unique fire-resistant anchors. 3M™ Ultra Fast Anchors offer an easy-to-install option for fire barrier systems. You need pliers to secure them, and no power tools are necessary. Flexible metal straps hold the fire barrier devices to fire-rated walls or floor and ceiling setups. You can install them in about one minute. To ensure structures stay safe under intense heat in factories or plants, check that the fire ratings of the anchors comply with the building codes.

Anchor Screws Designed for Metal in Areas with High Vibration

Machines and equipment often face vibration issues that call for special fasteners. Power-Bolt® anchors use a unique self-locking design with two expansion points. These points one at the sleeve and another at the cone, give them strong resistance to vibrations. The cone stays locked with the bolt, which stops it from loosening when vibrations occur. Wedge anchors work well in places like factories or areas with heavy equipment because they handle vibrations . When dealing with vibrations and temperature changes remember thermal expansion and contraction can loosen the anchor.

Conclusion

Choosing the right expanding screw is a big part of any heavy duty metal project. This article covered the important details to make sure fasteners hold up. You can protect safety and structure by using the right anchor for the load of the job.

Knowing tensile and shear forces is key to stopping early failures. Machinery creates moving loads that need extra attention and the right depth of the anchor will give you the strongest hold. Different expanding screws do different jobs. Wedge anchors are best for structural joints. Sleeve anchors adapt to various uses. Drop-in anchors fit overhead setups, and concrete screws make installs faster.

Using the correct installation methods affects how well things work. Drilling pilot holes the right way applying the correct torque, and being mindful when working with thin metal pieces all help achieve better results. It also depends on the environment. Outdoor areas with rough conditions need corrosion resistant materials. Fire rated options for industrial areas. High vibration areas need special fasteners to prevent loosening.

Small things like this can make the difference between a strong installation and one that fails. Now you can choose expanding screws knowing they will work with your metal projects. Taking the time to choose the right fasteners and install them avoids problems, saves money and keeps structures safe over time.

Key Points

To choose the right expanding screws for heavy duty metals you need to know the load and installation requirements.

- Match anchors to load: Different fasteners handle tensile and shear loads. In steel setups shear strength is about 60% of tensile strength.

- Choose screws for your job: Wedge anchors for structural steel, sleeve anchors for multiple tasks, drop-in anchors for overhead work, concrete screws for quick install.

- Follow installation steps: Use drill bits 2mm wider than the screw, tighten screws with calibrated wrenches for proper torque, don’t over-tighten thin metal plates.

- Consider environmental requirements: Outdoor setups need corrosion resistant materials like stainless steel. Factories need fire-rated anchors, areas with vibration need specific fasteners designed for movement.

- Check embedment depth: For heavy-duty jobs bolts need to go in at least 10 times their diameter. Lighter tasks need 7-8 inches to keep it secure and reliable.

Choosing the right fastener and installing it avoids costly problems and keeps structures strong over time even in tough metalworking conditions.

FAQs

- Q1. What are the main types of expanding screws for heavy-duty metal applications? Wedge anchors for structural steel, sleeve anchors for multiple metal applications, drop-in anchors for overhead metal fixtures and concrete screws like Tapcon® for metal mounting. Each has its own purpose in metalwork.

- Q2. How do you determine the load requirements when using expanding screws in metal? You need to consider both tensile and shear forces. Steel’s shear strength is 60% of its tensile strength. If you’re mounting machinery, include dynamic forces like vibration and impact in your calculations. Make sure heavy-duty anchors are embedded at least 10 times the diameter of the bolt.

- Q3. How do I install expanding screws in metal? Use a drill bit 2mm bigger than the screw diameter and tighten with a calibrated wrench to keep the torque right. Don’t over tighten in thinner metal sheets. If you’re working with hollow metal walls use toggle bolts or rivnuts instead.

- Q4. How do environmental factors affect the choice of expanding screws? Environmental conditions play a big role in choosing screws. Use corrosion resistant ones like stainless steel for outdoor use. Fire rated anchors may be required for industrial use. For areas with high vibration use fasteners that will stay secure like Power-Bolt® anchors with self-locking features.

- Q5. Why are expanding screws good for metal uses? Expanding screws have better hold than regular screws in thin or hollow materials. They spread the load across a bigger surface so less chance of something breaking. Some can be removed and used again making them useful for building work. They also work on solid materials like concrete, brick and cement.