Quick Summary: DeWalt DWE7491RS Table Saw Review

- Content Type: Hand Tested Review

- Affiliate Link Present: Yes

The DeWalt DWE7491RS table saw showed how tough it is after six months of working every day in my wood shop. It got a great score of 9.5 out of 10. It handled daily jobs very well, like a strong helper. This saw weighs 90 pounds and has a powerful 15-amp motor that spins at 4,800 rounds per minute. It cut through thick hard wood and thin wood easily. Many people say it’s the best table saw for work sites—and after using this dewalt 7491 a lot, I agree.

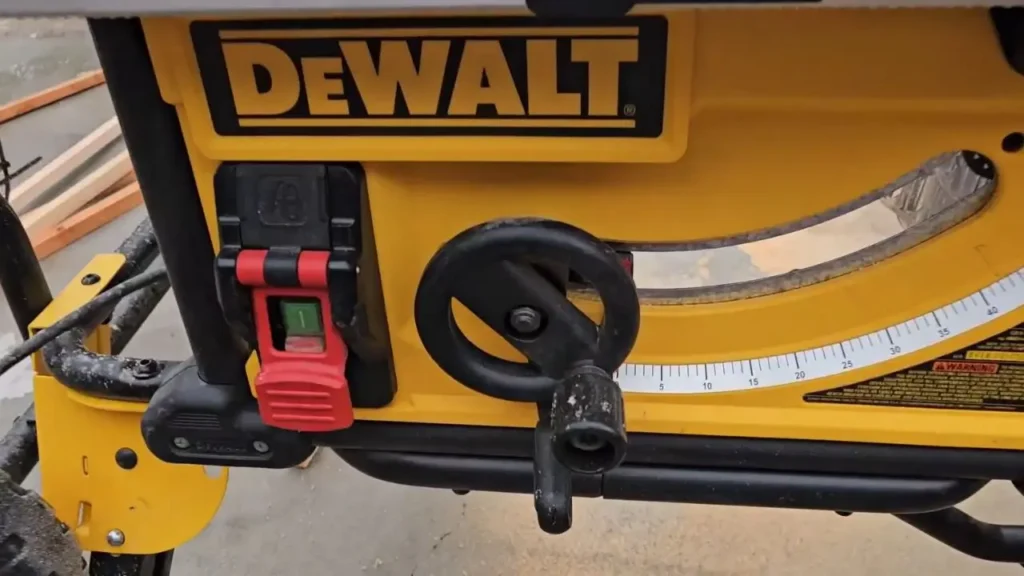

When I used the DeWalt DWE7491RS table saw, I saw how useful it was. It can cut wide pieces up to 32.5 inches. It also has a smart fence system that moves smoothly. This 10-inch saw was great because it could cut wood up to 3-1/8 inches thick when cutting straight (90 degrees). It could cut wood up to 2-1/4 inches thick when cutting at an angle (45 degrees). Safety parts, like the blade guard that looks like a shark fin and a well-covered power switch, made me feel safer using it. If you want to choose between different DeWalt table saws or need advice on this one, I will tell you what I learned about how it works, what could be better, and how to make it even better.

Disclaimer

Affiliate Disclosure

Hi, everyone; this is a heads-up about affiliate links you might see here. Our only purpose in including them is to help you find products easily if you are interested. There is no pressure to buy from these links, but also note that if you buy the products from these links, we may earn a small commission (at no extra cost to you). Your trust is important to us!

Learn more by reading our Full Disclosure.

Price Disclaimer

If we mention prices on **Tool Tested**, please keep in mind that prices can go up or down based on factors such as location, store policies, and whether the purchase is online or from a physical store. Each seller may have their own pricing structure.

Another important factor to consider is that the price we mention is based on the date of our review. It is possible that we purchased the tool long before that date, or that you are reading this review a long time after it was published, meaning the price may have changed.

Content Accuracy & Updates

The information on **Tool Tested** is for general help and information only. While we try to keep it correct and up-to-date, things can change. Always check facts, prices, and features with official sources before you buy or use any tool. Our reviews are based on our experience and research at the time of writing.

Safety & Professional Advice

Tools can be dangerous if not used correctly. Always read the tool’s manual and follow all safety warnings and rules. Wear proper safety gear like eye protection and gloves. The information in our reviews is not professional advice for building, electrical work, or any other skilled trade. If you need expert advice, please talk to a qualified professional.

DeWalt DWE7491RS Table Saw Details and How to Set It Up

When you open the box of the DeWalt DWE7491RS Table Saw, you will see a well-made table saw. It is built to be strong and easy to use at a work site. Using it for months helped me learn about its parts and how to set it up.

Motor: 15-Amp, 4,800 RPM Power

The main part of this saw is a strong 15-amp motor. It runs at a steady 4,800 rounds per minute. It doesn’t just sound strong—it really cuts well. The motor cuts thick hard woods without problems. It keeps its speed when cutting tough wood like treated wood or walnut. I saw how it kept working well when cutting hard maple many times. I did not need to stop for the blade to catch up.

Rip Capacity: 32.5 Inches with Flip Fence

A special part of this saw is that it can cut wide pieces. It cuts 32.5 inches on the right side of the blade and 22 inches on the left. This wide cutting area lets you cut big shelves and full sheets of wood easily. The fence system, which uses gears to move, shows how well DeWalt made this tool. It moves smoothly and does not slip like some cheaper saws.

The flip-over fence makes it even easier to cut narrow pieces. I like how the aluminum part, which is separate, can flip from one side to the other. It helps keep wide cuts steady by holding the edge of the wood. At the same time, it works as a low fence to make cutting narrow pieces safer.

Time to Assemble and Setting Up the Stand

It took me about 20 minutes to put everything together. This felt like a good amount of time for something so well-made. The rolling stand’s design was special. It has strong levers that let you push down with your foot to lower the bottom legs. Setting it up is quite simple. First, you stand it up straight and open all four legs until they lock in place. Then, you step on the pedals to push out the bottom legs. After that, you hold the top handle to get the saw ready to use.

Weight and How Easy It Is to Move

Even though the DWE7491RS weighs 90 pounds with its rolling stand, it is still easy enough to move for people who work with tools. Its frame is made of steel tubes. This makes it strong without being too heavy to handle. It has two strong wheels that help you move it easily and keep it steady. If your workshop space is small, its fence rails can slide in. This makes the saw smaller and easier to put away.

How It Cuts After 6 Months of Use

I have made hundreds of cuts for different projects. So, I have really tested what the dewalt 7491 table saw can do. My experience shows how well this small but strong tool handles real wood working jobs.

How Accurate It Is on Plywood and Hardwood

The 15-amp motor cuts through all types of wood I have tried. It handles everything from 3/4-inch plywood to heavy hard wood without losing cutting quality. When cutting 8/4 maple or walnut, the saw works well if you push the wood through slowly. For lighter wood like 1/2-inch or 3/4-inch hard wood, it cuts through easily. But cutting longer 1-inch maple boards can be a bit hard. It is possible but slower and sometimes leaves burn marks.

Fence Straightness and Blade Parallelism

The fence system, which uses gears, is a key part because it stays straight with the blade even after many changes. But after using it for six months, I saw a very small problem where it was not perfectly straight. This means it needs to be fixed a little sometimes. I always measure from the same spot at the front and back of the blade to make sure it stays straight. To make the fence perfectly square, some people suggest adding small pieces of wood where the fence connects to the rail. My fence leans a little towards the blade, about 1mm off. But this small difference has not messed up how accurate my cuts are.

How Bevel and Depth Adjustments Work

The depth adjustment worked well at first. But the saw’s shaking made it get loose over time. Fixing this was easy by tightening a certain nut and putting white grease on the moving parts. To change the angle of the cut (bevel), I found out that you need to adjust a special part to get exact 45-degree cuts. Getting a perfect 90-degree straight cut sometimes needs you to push hard on the stop.

Dado Blade Use and Results

This saw can use dado blades that are up to 13/16 inches wide and 8 inches big. To use it, you need a special part called the DWE7402DI dado throat plate. I use a 6-inch dado blade set that has two cutting parts. This gives a good mix of power and smooth cutting. The saw does a good job with dado cuts, but you need to push the wood through more slowly to get clean edges. The smaller motor can struggle when cutting thick hard woods. But it works well for softer wood and is great for simple cabinet joints.

Changes and Small Fixes That Helped A Lot

Even a good saw like the dewalt 7491 can be made better with the right changes. After trying different ideas, I found a few small fixes that made cuts more accurate and made the saw work better.

Zero Clearance Insert for Cleaner Cuts

The original plate around the blade has a big gap. This often causes wood to splinter on thin materials. I changed it with a “zero clearance” insert. This insert is made from 1/2-inch MDF wood and cut exactly to fit. This simple change stopped splinters on plywood edges. It also kept small pieces of wood from falling into the blade area. The insert has screws to adjust its height. Remember, you will need to switch back to the original plate when making angle cuts.

Crosscut Sled to Make It Safer and More Accurate

To make it safer and more accurate, I built a crosscut sled. I used strong plywood and oak strips that fit into the saw’s slots. I made the strips a little thinner than the slots so they move without shaking. The sled also has a special track to add other parts and a stop block. This is helpful for making many cuts that are the same size. This has been a big help for cutting smaller pieces. It keeps my hands away from the blade and gives me better exactness and trust.

Foldable Outfeed Table to Hold Big Sheets

Maybe the biggest change I made was building a folding table that extends from the back of the saw. I made mine the same width as the saw table (26 inches) and 24 inches long. A frame made of 2×2 wood pieces connects to the saw with “L” shaped metal parts. This extra table sits just below the saw table’s level. This setup helps wood slide smoothly without getting stuck. Adding it has made working with longer boards much safer and easier. It also folds away when I am not using it. This is good because my workshop does not have a lot of space.

UHMW Fence Upgrade with Sacrificial Fence

To make the fence slide smoother, I added UHMW plastic to the original fence. One side now has a very slippery surface. I use the other side as a “sacrificial” fence when making dado cuts (grooves). If you are looking for other options, companies sell fence upgrades with three slots. These let you add things like featherboards (to hold wood down) or stop blocks.

Better Miter Gauge for Cutting Angles

I changed the original miter gauge with a new one that can be adjusted to stop any wobbling in the slot. This new part gives me more exact angle settings and has an adjustable fence with a stop. Because of this, I do not use my miter saw anymore. I can now cut angles right on the table saw.

Is the DWE7491RS a Good Choice for Pros and DIYers?

Deciding if you should buy the DeWalt DWE7491RS table saw means looking closely at what it offers. This is important for both professional workers and people who do projects at home. After many tests, I have looked at how its price has changed. I have compared it to similar tools. And I have thought about who would get the most benefit from it. This helps you decide if it should be in your workshop.

Price History and Best Time to Buy

The DeWalt DWE7491RS table saw has had some big changes in price over the last few years. Right now, it costs $882.91 from other sellers as of May 2025. This is much higher than its lowest price ever. Back in October 2023, the saw dropped to $474 on Amazon (check current price). That was a great time to buy one. You can also find more details on the official DeWalt product page. Before that, prices were usually between $550 and $650.

- Rack & Pinion Telescoping Fence System Make fence adjustments fast, smooth and accurate

- Patented material support, can be used for narrow rip cuts.

- 32-1/2″ rip capacity easily cuts a variety of larger shelving and trim materials

Past trends show September and October are the best months to buy. In previous years, prices often drop during this time. Waiting for these seasonal sales might save you $200-400 compared to the highest prices. If the current price is over $650, it is better to wait unless you really need it for a project now.

Comparing It with SawStop and Bosch

DeWalt’s DWE7491RS is somewhere in the middle when you compare it to its main competitors. The SawStop Jobsite Pro costs $1,299. It offers very high safety with its technology that can sense skin. On the other side, Bosch’s 4100-10 is around $500-600, making it a cheaper choice.

DeWalt stands out because of its fence system that uses gears. This part is very strong and makes adjustments easy. But, other tests showed that the Bosch GTS10 XC is more accurate. The SawStop is just as well-built as the others and has advanced safety features, but it cannot cut as wide pieces.

Who Should Think About This Table Saw?

This DeWalt model is good for a few specific types of buyers. It is great for professionals who need a tool that is easy to move but still cuts well. People who install cabinets, work with hard wood floors, and do trim carpentry will find it useful. With its 32.5-inch cutting width, the saw is also perfect for deck builders and remodelers who cut large sheets of material.

For more advanced projects, this saw gives skilled DIYers and hobbyists a clear step up from basic models. It has features found in professional tools and costs a reasonable amount. However, if safety is the most important thing and you have enough money, the SawStop is a good choice, even if it costs more. If you need to move your saw around but still want accurate cuts for making furniture, this DeWalt model is a great balance between those two needs.

Conclusion

Summary of My Experience

After using the DeWalt DWE7491RS every day for six months straight, I can say it has become the most important tool in my workshop. This 10-inch table saw has serious power and handles almost any wood working job easily. Its 15-amp motor manages both thick hard woods and thinner trim cuts without any trouble, and it stays reliable all the time.

One thing that really impressed me during all this time is its fence system that uses gears. It is as precise as expensive, fixed saws, and that is not something you would expect in a portable saw. Its 32.5-inch cutting width also helped a lot for cutting large sheets of material while keeping cuts accurate. Over time, I had to fix it a little here and there. But that feels fair considering how easy it is to move and how capable this saw is.

The DWE7491RS is priced between cheap tools and very expensive ones like SawStop. Professionals who need a portable saw for job sites that still cuts strongly will find this model very valuable. At the same time, skilled DIYers who want to move up from basic setups can enjoy its advanced features without spending too much money.

My Final Recommendation and Buying Advice

My changes, like adding a zero-clearance insert, a crosscut sled, and a folding outfeed table, made a good saw into the main star of my workshop. These simple fixes solved the few problems I had when using it a lot. Also, you can save a lot of money by buying it during fall sales. That makes this already great tool an even smarter buy.

The DeWalt DWE7491RS gives you what is most important: reliable performance, smart features, and the ability to use it for professional jobs or serious DIY work. Even though it weighs 90 pounds, the strong rolling stand makes moving this powerful saw between job sites or around a workshop easier than you would think. I suggest this table saw to any woodworker who wants the best mix of accuracy, strength, and easy moving.

Important Note: Prices and products can change. Always check the official websites or trusted shops for the newest information.